Product List

- Products Supported

- Products Supported (by Manufacturer)

- APS “Black Steel” Brake Discs & Linings

- Goodyear Aviation Tyres

- Precision Airmotive

- BASF

- Chicago Miniature Lamps

- Concorde Batteries

- Esterline Sensors

- Eaton

- Essex PB&R

- Goodrich

- HK Porter

- HR Smith

- Meggitt ABS

- NMB Minebea UK Ltd

- Michelin Condor

- RBC Bearings

- Sennheiser

- Sofrapaint

- SKF Aerospace France (Sarma)

- SKF (UK) Ltd

- Parker – Cleveland Wheel & Brake

- Teledyne Gill

- Tempest

- Timken

- Triumph Controls

- Airframe Components

- Avionics & Instruments

- Electrical Power & Batteries

- Engine Accessories & Services

- Equipment & Furnishings

- Filtration

- Fuel Systems

- Ground Support

- Hardware & General Consumables

- Hose & Fittings

- De-Ice

- Ignition Systems

- Landing Gear

- Lighting

- Oxygen, Emergency & Safety

- Paints & Chemicals

- Hose shop overview

- Pilot Supplies

- Products supported (Alphabetically)

- Propellers

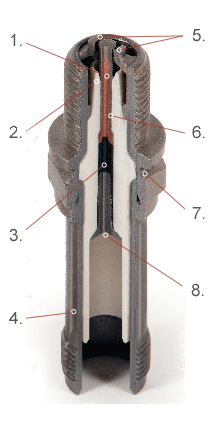

Tempest Spark plugs

Saywell International hold a large inventory of Tempest spark plugs in stock ready to ship to you today, please use the Tempest aviation spark plug application guide to choose the right plug for your requirements.

The Tempest spark plug is the most innovative spark plug available in the aviation industry with many features which make it the worlds best Aviation spark plug:

1. High Conductivity Copper Core Centre Electrode

Copper, co-extruded inside a nickel alloy sleeve ensures outstanding heat and electrical conductivity while the nickel sleeve offers high resistance to corrosive combustion gases.

2. High Alumina Ceramic Insulator

High mechanical strength, superior dielectric properties, proprietary protective glaze, provides high performance to conquer severe operational conditions. “Clean Collar™” massive electrode “V” tip focuses heat to reduce fouling and enhance heat range control.

3. Proprietary Glass Centre Seal

21st century ‘fired in’ resistor replaces the multipart screw, spring, carbon pile stack up used in competitive plugs and known to suffer from resistance value instability that can cause misfires, wasted fuel, engine roughness.

4. Nickel Finish

Environmentally preferable electrolytic nickel provides outstanding durable finish, superior corrosion protection, and extreme wear resistance.

5. Nickel Ground Electrodes

Aviation grade nickel electrode design focuses on minimising sparking voltage requirements while maintaining specification gaps to ensure large, stable ‘flame kernels’ for on-time ignition and complete combustion

6. Vacuum Infused Centre Electrode

Proprietary, vacuum infusion process seals electrode/insulator gap providing stable heat range and superior centre electrode cooling (heat flow to the insulator).

7. Hot-Lock Assembly

Intense pressure and heat create positive, zero-leakage, shrunk in seal between insulator and shell to contain the hot, high pressure combustion cycle gases.

8. Harness Wire Contact

Smooth, uninterrupted, oxide treated spring contact surface offers enhanced corrosion resistance, is chemically bonded to the fired-in resistor providing the ultimate harness/spark plug termination integrity and energy transfer.

14th May 2024

Conidia Fuelstat Plus fuel testing kit distribution

8th Jan 2024

Goodwood Charity Track Days Dates for 2024

24th Nov 2022

Ontic appoints Saywell as their exclusive distributor for India

18th May 2022

BAE Systems appoint Saywell as their approved supplier of spares for all regional aircraft type.